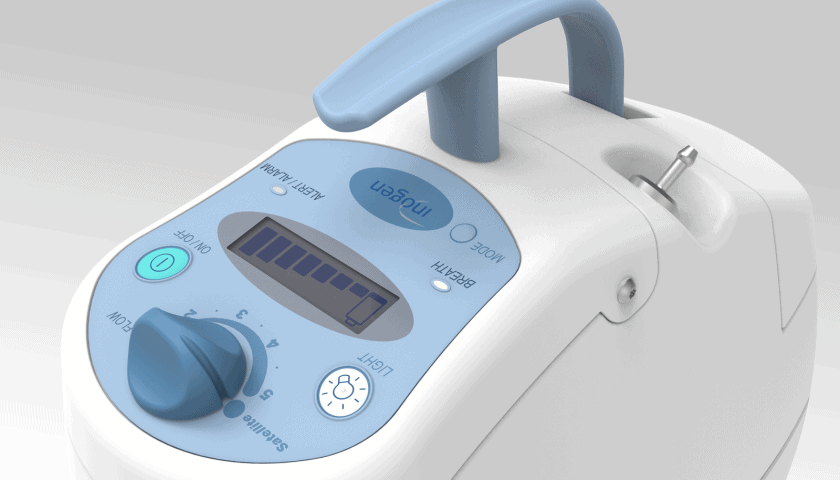

Inogen Oxygen Concentrator

When we first met the Inogen group, they were already familiar with our work on the HELiOs Personal Oxygen System the conserver we had developed for Nellcor Puritan-Bennett three years before. Inogen wanted us to duplicate this success for them in the oxygen concentrator market. An oxygen concentrator is a device that cleans nitrogen from ambient air and supplies a continuous flow of pure (about 95%) oxygen to the user by way of an air tube called a nasal cannula.

The conserver market has boomed, largely due to the success of the HELiOs™ system.

The main issue with these types of devices is that they require refilling from a large liquid oxygen tank every few hours. Concentrators don’t need refilling, but for other reasons, business has not fared so well. Inogen’s idea was to re-think the technology and re-define the category.

The concentrator market had been in decline for many years. For COPD patients on the go, concentrators added a degree of mobility, but the units were big and noisy, and needed to be connected to a wall socket. It was also difficult to sell a product that was industrial looking and heavy to lug about. Inogen planned to develop a lightweight, efficient, and quiet portable oxygen concentrator that could run on batteries.

Start-up company needed help developing a funtional prototype.

The start-up company presented us with a very preliminary prototype that worked, but had only limited functionality. They had already completed a portion of the initial development and had identified some proprietary components they wanted to incorporate into the final design. Their plan was to use off-the-shelf parts, hire us for the I.D., and make a real product out of what they had. But like most of the devices we develop, almost all of the components eventually had to be custom designed.

Over the period of about a year, their group completed the electronics and software development. Concurrently, Omnica performed the industrial design, mechanical layout, the internal and external packaging, battery case, chargers, carts, the satellite conserver valve, the manifold design, and the extrusion and chassis assembly. Omnica worked with other vendors to successfully miniaturize the pneumatics and valving for use in the lightweight design. We even built the production test equipment, the manifold leak testers, and later approved the first articles.

We fabricated 18 pre-production prototypes of the Inogen One OxygenConcentrator System™.

Our client used them to introduce the product in a trade show. Reaction to the new device was overwhelming, and on that basis, the company made projections of how many units to manufacture as a first run of the product. Six months later, when the concentrator actually became available to the market, they had to dramatically revamp production forecasts to keep up with rapidly rising demand.

The concentrator runs on batteries and is approved for use on most airlines.

The Inogen One Oxygen Concentrator System fulfilled the promise of independence for highly active home oxygen patients. It weighs 10 pounds, and runs for 2 to 3 hours on rechargeable batteries (indefinitely on A/C). It is very quiet and features a breath detection system four times as efficient as other concentrators. The Inogen One is the only oxygen concentrator which meets 100% of FAA requirements for use upon aircraft. It has won three awards including the prestigious MDEA design excellence award.

Electrical Engineering

Ergonomics

Industrial Design

Mechanical Engineering

Model Making

Photo Renderings

UX Design