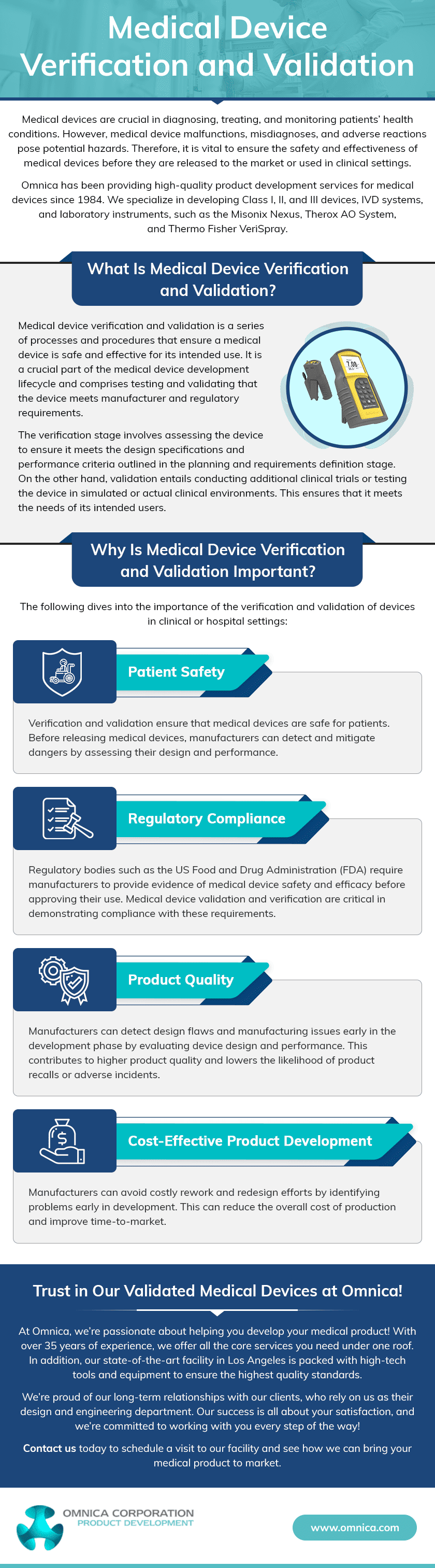

Medical devices are crucial in diagnosing, treating, and monitoring patients’ health conditions. However, medical device malfunctions, misdiagnoses, and adverse reactions pose potential hazards. Therefore, it is vital to ensure the safety and effectiveness of medical devices before they are released to the market or used in clinical settings.

Omnica has been providing high-quality product development services for medical devices since 1984. We specialize in developing Class I, II, and III devices, IVD systems, and laboratory instruments, such as the Misonix Nexus, Therox AO System, and Thermo Fisher VeriSpray.

What Is Medical Device Verification and Validation?

Medical device verification and validation is a series of processes and procedures that ensure a medical device is safe and effective for its intended use. It is a crucial part of the medical device development lifecycle and comprises testing and validating that the device meets manufacturer and regulatory requirements.

The verification stage involves assessing the device to ensure it meets the design specifications and performance criteria outlined in the planning and requirements definition stage. On the other hand, validation entails conducting additional clinical trials or testing the device in simulated or actual clinical environments. This ensures that it meets the needs of its intended users.

Why Is Medical Device Verification and Validation Important?

The following dives into the importance of the verification and validation of devices in clinical or hospital settings:

Patient Safety

Verification and validation ensure that medical devices are safe for patients. Before releasing medical devices, manufacturers can detect and mitigate dangers by assessing their design and performance.

Regulatory Compliance

Regulatory bodies such as the US Food and Drug Administration (FDA) require manufacturers to provide evidence of medical device safety and efficacy before approving their use. Medical device validation and verification are critical in demonstrating compliance with these requirements.

Product Quality

Manufacturers can detect design flaws and manufacturing issues early in the development phase by evaluating device design and performance. This contributes to higher product quality and lowers the likelihood of product recalls or adverse incidents.

Cost-Effective Product Development

Manufacturers can avoid costly rework and redesign efforts by identifying problems early in development. This can reduce the overall cost of production and improve time-to-market.

Trust in Our Validated Medical Devices at Omnica!

At Omnica, we’re passionate about helping you develop your medical product! With over 35 years of experience, we offer all the core services you need under one roof. In addition, our state-of-the-art facility in Los Angeles is packed with high-tech tools and equipment to ensure the highest quality standards.

We’re proud of our long-term relationships with our clients, who rely on us as their design and engineering department. Our success is all about your satisfaction, and we’re committed to working with you every step of the way!

Contact us today to schedule a visit to our facility and see how we can bring your medical product to market.